Tow Cutter Systems

With over 40 years in the business, DM&E has supplied equipment to fiber producers on every continent. Our machines are responsible for processing virtually every synthetic fiber available. We continue to manufacture, repair, restore, and modify cutters and associated equipment for all major fiber producers throughout the world. Our process experience ensures that your DM&E equipment will efficiently produce the best staple fiber.

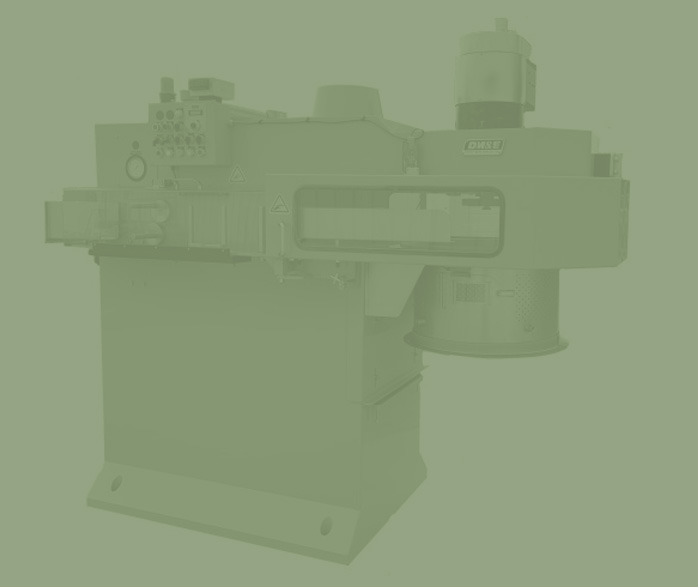

Tow Cutters

As the only company in the world that focuses on staple fiber processing equipment, DM&E is the global standard for radial blade tow cutters. With 20, 40, 60, 90, and 120 Series cutters, as well as Mk4 and Mk5 cutters, we can meet the requirements of all fiber producers around the world. This includes processing tow from 10,000 denier at 50 meters per minute to 8,000,000 denier at 450 meters per minute. Ongoing research and development at DM&E ensure that our clients receive high-quality equipment that improves their staple fiber productivity and overall efficiency.

Tension Stands

Pre-cutter tow tension is an integral part of the cutter system. It’s critical to the consistency of fiber cut length and cut quality. DM&E offers several tow tension stand options that will optimize your staple fiber production. These cutter/tension systems are controlled by PLC systems and can be integrated into other control and operation systems upstream and downstream. This provides much more than stand-alone cutters.

More about DM&E Tow Cutter Systems

The flexibility, accuracy, and simplicity of DM&E tow cutters have made them essential for various industries in the staple fiber market. All DM&E tow cutters are custom built and incorporate all safety features with electrical interlocks, assuring safe access to the tow and cutter reels. Cutters also feature a pneumatic presser wheel mechanism that prevents damage to cutter reels if there is a blockage in the cutting zone. Presser wheels can be adjusted easily to maintain presser wheel to blade clearance. Also, all cutters have modern variable speed electronic drives with frequency and voltage available for any requirement.

Because proper tow presentation is essential to cutting quality staple fiber, DM&E cutters have a sophisticated tow guiding system that allows vertical or horizontal presentation to the cutter reel. Additionally, right- or left-hand operation is available on all tow cutters. All cutters are equipped with the DM&E Cutting Load Meter as standard.

Watch 40 Series Cutter video below on blade installation, cutter reel installation and threading of a tow band.

Resources

Tow Cutter Comparison GuideTension Stand Comparison Guide

Spec Sheets for:

20 Series Tow Cutter40 Series Tow Cutter60 Series Tow Cutter90 Series Tow Cutter120 Series Tow CutterMK4 Radial Blade Tow CutterMK5 Radial Blade Tow Cutter310 Motor Controlled Regenerative Tension Stand310 Series Brake Controlled Tension StandMk4 Tension Stand

Need More Info/Help?

Let our equipment specialists help you determine the best solution for your process.