Tow Crimpers & Repair

Much the same as DM&E’s work with tow cutter repair resulted in the manufacturing of its own line of cutters, our work with tow crimper repair led to the manufacturing of DM&E crimpers. DM&E has the technology, engineering, and process experience to meet all tow crimper needs, whether it is rebuilding, repairing, or replacing your current equipment. We are committed to providing fiber producers with high-quality, precision work and sound engineering, so they are able to produce the very best staple fiber.

Tow Crimpers

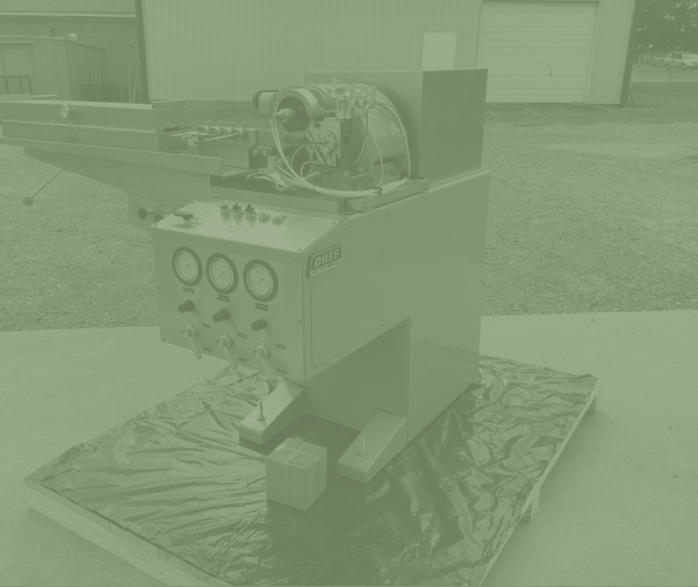

Tow crimpers manufactured by DM&E are versatile, high-quality, and designed to provide the options and configurations staple fiber producers need for their specific applications. Our tow crimpers utilize stuffing box crimping, one of several texturing methods that allows for new application fields and higher quality staple fiber. We manufacture small and medium-sized tow crimpers (for processing tow from 30,000 denier [33 ktex] to 1,500,000 denier [151 ktex]). The collection of tow crimpers offered by DM&E are designed for light to medium production requirements, and it includes the CL-05, CL-21, and WA models.

Tow Crimper Repair

Whether your tow crimper requires repair, rebuilding, or replacement parts, DM&E has it covered. We know that tow crimper parts, like the stuffing box components and crimper rolls, require maintenance and sooner or later, repair. Proper upkeep by trained professionals provides staple fiber producers with reduced downtime and consistent, high-quality products. We offer repair services for all makes and models of tow crimpers, whether they are DM&E or others like Neumag or Fleissner. Working with DM&E ensures that fiber production is consistent and precise and that our clients experience as little downtime as possible.

Your crimper parts are inspected before any work is done. A detailed worksheet is completed with the dimensions and notes of any problems. Each part is serialized for permanent records. Once the scope of the work is determined a detailed quotation is submitted. After approval repairs and replacement begins. After all work is complete, everything is inspected and verified before shipping. The completed inspection sheet is retained.

DM&E Tow Crimper Rebuild Service

DM&E rebuilds and repairs parts for all crimpers. We will also rebuild your crimper to new condition. This is a detailed service that can restore your aging crimper carcass to new condition. Everything is disassembled and all dimensions verified. Bearing bores and stuffing box mountings are refinished. Pneumatic and hydraulic components are replaced or rebuilt. Bearings and seals are replaced. We can reconfigure the size and stuffing box geometry, or adapt the crimper to match a different installation. Here is an opportunity to make that old crimper an effective partner to your production.

See some of DM&E’s Crimper Repair and Rebuild support.

Need More Info/Help?

Let our equipment specialists help you determine the best solution for your process.